XT-D Taxanaha xawaaraha sare ee flexo daabacaadda mishiinka dhejiska

Dhammaan qalabka korantada ee mishiinka oo dhan waxay ka samaysan yihiin noocyo caan ah oo caalami ah, oo leh tayo xasilloon oo la isku halleyn karo.

Interface-ka-mashiinka-mashiinka, maamulka nidaamka kombuyuutarka, hawlgalka ku habboon iyo isbeddelka degdegga ah.

Qalabka waxaa lagu hayn karaa meel fog iyada oo loo marayo shabakadda, si loo xukumo oo loo xalliyo qaladka qalabka si dhakhso ah, loo hagaajiyo waxtarka dayactirka oo loo yareeyo kharashka dayactirka.

Mashiinka oo dhan waxaa loo qaabeeyey oo loo soo saaray iyadoo loo eegayo waxqabadka sare iyo badbaadada sare iyo dhammaan mishiinka oo dhan wuxuu waafaqsan yahay heerka CE ee Yurub.

Qalabyada iyo qaybaha muhiimka ah ee mashiinka oo dhan waxaa lagu daaweeyaa gabowga iyo xanaaqa si loo baabi'iyo walaaca gudaha ee birta.

Warshada birta ayaa soo saartay si waafaqsan warqadda dhakhtarku qoray.Qalabka cayriin waa XN-Y15MnP, HRC 40-45, Xoog-xoojintu waa 450-630, Wax-soo-saarka in ka badan 325

Dhammaantood waa dhulka CNC. Waxaan leenahay 8 pcs mashiinnada CNC.

Dhammaan mashiinnada xashiishka iyo rollers waxay ka samaysan yihiin bir tayo sare leh, dabacsanaan, deminta iyo daaweynta xanaaqa;Shiididda, saxitaanka dheellitirka firfircoon ee kombuyuutar sax ah oo sarreeya, chrome adag oo dusha ku dhejisan.

Dhammaan qalabka gudbinta mishiinku waxay ka samaysan yihiin bir tayo sare leh, carburizing, daweynta deminta iyo daawaynta shiididda si loo hubiyo inay leeyihiin daabacaad sax ah oo sarreeya oo shaqeynaya muddo dheer.

1.Material: 20CrMnTi aluminium bir ah, carburized, Demay iyo dhulka.

2.Level 6 saxnaanta, hawlgalka siman, qaylada hoose, adkaanta HRC58-62, nolol dheer oo adeeg ah, ma xirna 10 sano gudahood, diiwaangelinta daabacaadda muddada dheer waa la gaari karaa.

Qaybta gudbinta (isku xirka iligga usheeda dhexe) ee mashiinka oo dhan waxay qabataa isku xirka furaha (gacanta ballaarinta) si loo baabi'iyo nadiifinta wadajirka ah ee isku xirka, oo ku habboon hawlgalka xawaaraha sare ee muddada-dheer oo leh torque weyn.

Saliidda buufinta .Cutub kastaa waxaa lagu qalabeeyaa aalad dheellitirka saliidda si loo hubiyo dheelitirka saliidda ee haanta saliidda ee unug kasta.Mashiinka orso oo dhan ayaa leh dalool buuxin, oo ay fududahay in la buuxiyo.

Qaybaha gudbinta ugu muhiimsan ee mashiinka oo dhan waa dhammaan xoojinta is-dhexgalka, kuwaas oo leh nolol dheer oo adeeg ah, dayactir ku habboon iyo saxnaanta sare waxay ku hayaan qalabku inuu ku socdo xawaare sare muddo dheer.

Matoorka ugu muhiimsan wuxuu qaataa matoorka beddelka soo noqnoqda, xakamaynta beddelka soo noqnoqda, kaydinta tamarta, bilaw xasiloon, oo leh qalabka ilaalinta bilawga mootada.

Qalabka wax-soo-saarka sawirka gaarka ah, mashiinka hortiisa wuxuu daawan karaa shaqada gadaal, si loo joojiyo quudinta warqadda haddii ay dhacdo xaalad degdeg ah, yareyso qashinka.

Iftiinka heerka cusub, oo tilmaamaya heerka bilawga mashiinka (qaabka horusocodka kombuyuutarka), oo muujinaya heerka shaqada ee mashiinka, oo tilmaamaya macluumaadka qaladka mashiinka.

Unuggii mashiinka oo dhan ayaa mid mid si toos ah u kala saari kara hal badhan.

Shaft SFC waa la qalabeeyay, (Cromate Full toosan), aad u adag, si fiican uma daxalaysan.

Adag:HRC60°±2°; Adagnaanta:0.8-3mm;Surface Roughness

Waaxda xakamaynta kumbuyuutarka

Mashiinka iyo qalabka korantada dhamaantood waxa ay ka samaysan yihiin noocyo caan ah: shaashad taabasho ah (interface-ka-mashiinka-mashiinka).

Eberaynta mishiinka, booska hore loo dhigay iyo toosinta saxanka otomaatiga ah: daabacaadda, eberaynta wejiga iyo preset-ka si loo hubiyo in dhammaan daabacaadda looxa kowaad la geliyo, oo looxa labaadna asal ahaan la hagaajiyo, kaas oo magdhow u ah khaladaadka inta lagu jiro hawlgalka.

Shaqada dib u habeynta xusuusta: marka saxanka daabacaada uu u baahan yahay in la dayactiro ama la tirtiro, shaqadan waa la isticmaali karaa.Dayactirka ama tirtiridda ka dib, waxay si toos ah dib u dejin doontaa iyada oo aan la hagaajin.

· Shaqada kaydinta wajiga dalbo: 999 waji ayaa la kaydin karaa.Kadib dalabka la kaydiyay, qalabku wuxuu si toos ah u xafidayaa booska wajiga ee saxanka daabacaadda.Marka xigta ee amarka kaydsan la furo, ka dib marka saxanka la sudho, qalabku wuxuu si toos ah ula qabsan doonaa booska saxda ah ee xusuusta, taas oo si weyn u badbaadinaysa wakhtiga hagaajinta ee beddelka amarka.

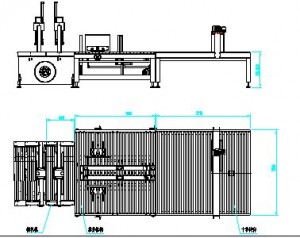

| Shayga | Unug | 1226 qaab |

| Ballaca gudaha ee baffles | mm | 2800 |

| Cabbirka xaashida | mm | 1270×2600 |

| Daabacaad wax ku ool ah | mm | 1200×2400 |

| Cabirka mashiinka min | mm | 320×640 |

| Dhumucda saxanka daabacaadda | mm | 7.2 |

| Xawaaraha shaqada | xaashi/daqqo | 0~180 |

| Awoodda dhaqdhaqaaqa ugu weyn | KW | 15 ilaa 30 |

| Wadarta awooda | KW | 35-45 |

| Miisaanka | T | ≈20.5 |

| Saxnaanta sare | mm | ±0.5 |

| Slotting sax ah | mm | ± 1.5 |

1.Sida shuruudaha foorarsiga kala duwan ee waraaqaha waraaqaha, mugga hawada waxaa lagu hagaajin karaa si loo hubiyo sahayda waraaqaha siman.

2.Dhammaadka dambe ee mishiinka waxaa lagu qalabeeyaa koontaroolka isdhexgalka si loo xakameeyo quudinta warqadda joojinta degdegga ah.

3.Servo Controller waxaa loo isticmaalaa in lagu xakameeyo quudinta waraaqaha iyo joojinta quudinta waraaqaha, taas oo ah mid degdeg ah oo badbaado leh.

4.It waxay qabataa cadaadiska patented ee bilaashka ah ee hogaaminaya nidaamka quudinta warqadda rullaluistemadka (afar saf oo taayir quudin warqad ah, saf kasta oo taayirrada quudinta warqad ah ayaa lagu qalabeeyaa matoor si gooni ah loo wado, isla mar ahaantaana, waxay bilaabataa oo istaagtaa at waqtiyo kala duwan si loo xaqiijiyo quudinta warqadda fidsan).Ma jiraan wax ifafaale ah oo ku yaal sabuuradda jiingadaha, taas oo si weyn u wanaajisa cadaadiska kartoonka.

5.Jagooyinka dhinaca bidix iyo midig iyo sanduuqyada joogsiga dambe waxaa lagu hagaajiyaa koronto;farqiga u dhexeeya baffles hore waxaa lagu hagaajiyaa gacanta.

6.Septum feeder (quudinta joogtada ah ama septum ayaa loo dooran karaa sida loo baahdo).

7.Feeding counter, dhigaya oo soo bandhigaya tirada wax soo saarka.

2. Qalab ka saara siigada:

1.Buraashka qaybta quudinta waraaqaha iyo nuugista hawada sare iyo qalabka ka saarista boodhka ayaa si weyn uga saari kara wasakhda dusha daabacaadda ee waraaqaha waxayna wanaajisaa tayada daabacaadda.

3

1.Upper rullaluistemadka: Dhexroorka dibadda waa ¢ 87mm tuubo bir qaro weyn, qalabaysan laba siddo quudinta warqad.

rullaluistemadka 2.Lower: Dhexroorka dibadda waa ¢ 112mm tuubo bir qaro weyn, dusha waa la shiiday iyo chrome adag.

3.Dial dial ka gaab rollers quudinta warqad waxaa lagu hagaajiyaa gacanta, iyadoo kala duwan ee 0-12mm.

4.Aaladaha eber-ka tooska ah:

1. Quudinta , daabacaadda iyo boos bixinta ayaa si toos ah dib loogu dejinayaa eber.

2. kartoonnada guud waxay isticmaalaan qalabka eber si toos ah, isku day inaad daabacdo laba jeer ayaa lagu hagaajin karaa booska saxda ah, yaraynta qashinka kartoonada.

II.Waaxda Daabacaadda(Ikhtiyaarka koowaad - lix unug midab)

1, Roller-ka daabacaadda

1.Outer dhexroor ¢ 405.6mm (oo ay ku jiraan saxan dhexroor dibadda ¢ 420mm)

2.Steel dusha tuubada waa dhulka iyo chrome adag.

3. Samaynta dheelitirka sixitaanka, oo si habsami leh u socodsii.

4.Ratchet usheeda dhexe ee gariiradda go'an.

5.The full version ka laadlaad jeexdin ah ayaa lagu dabaqi karaa 10 mm × 3 mm xadhig ka laadlaadda.

6. Soo dejinta iyo dejinta saxanka daabacaadda, cagaha beddelka kontoroolka korantada horay iyo gadaal.

2, Daabacaadda rullaluistemadka

1. Dhexroorka dibadda waa ¢ 176mm.

2.Steel dusha tuubada waa dhulka iyo chrome adag.

3. Samaynta dheelitirka sixitaanka, oo si habsami leh u socodsii.

4.Dial gap rullaluistemadka saxaafadda daabacaadda waxaa lagu hagaajiyaa gacanta, iyadoo kala duwan ee 0-12mm.

3. Quudinta rollers sare iyo hoose

1.Upper rullaluistemadka: Dhexroorka dibadda waa ¢ 87mm tuubo bir qaro weyn, qalabaysan saddex siddo quudinta warqad.

rullaluistemadka 2.Lower: Dhexroorka dibadda waa ¢ 112mm tuubo bir qaro weyn, dusha waa la shiiday iyo chrome adag.

3.Dial dial ka gaab rollers quudinta warqad waxaa lagu hagaajiyaa gacanta, iyadoo kala duwan ee 0-12mm.

4. Birta anilox roller

1. Dhexroorka dibadda waa ¢ 212 ㎜.

2.Steel tuubada dusha shiidi, anilox la riixay, chrome adag.

3. Samaynta dheelitirka sixitaanka, oo si habsami leh u socodsii.

4.Tirada mesh waa 200,220,250,280 marka loo eego fursadahaaga

5. Iyada oo nidaamka quudinta waraaqaha pneumatic si toos ah u qaadida qalabka (inta lagu guda jiro quudinta warqad, rullaluistemadka anilox soo degtaa si ay ula xiriirto saxanka, iyo marka quudinta warqaddu joogsato, rullaluistemadka anilox kor u kacaya si ay u kala soocaan saxanka).

6.Anilox rullaluistemadka leh - block nooca xajin xad dhaaf ah, fududahay in la dhaqo khad.

5

1. Dhexroorka dibadda waa ¢ 195mm.

2.Tuubada birta ah waxaa lagu dahaadhay caag u adkaysta oo dheellitiran.

3.Rubber dhexdhexaad sare shiidi gaar ah, saamaynta wareejin khad wanaagsan.

6. Habka hagaajinta wajiga

1.Dhismaha qalabka Planetary.

2.Printing wajiga koronto digital 360 ° hagaajinta.(shaqaynta iyo joogsiga waa la hagaajin karaa)

3.Manually hagaajin booska toosan, iyadoo wadarta fogaanta hagaajinta ee 14mm.

7. wareegga khad

1.Pneumatic diaphragm bamka, sahayda khad xasilloon, hawl fudud iyo dayactir.

2.Shaashada khad, shaandhaynta wasakhda.

3.Haanta khad caaga ah.

8, Qalabka hagaajinta wajiga daabacaadda

1.Cylinder nooca biriiga.

2.Marka mishiinka la kala saaro ama marxaladda la hagaajiyo, habka bareegga ayaa xaddidaya wareegga mashiinka oo wuxuu hayaa barta go'an ee booska asalka ah.

9, Qalabka hagaajinta wajiga daabacaadda

1.Brigii Silinder

2.Marka mishiinka la kala saaro ama marxaladda la hagaajiyo, habka bareegga ayaa xaddidaya wareegga mashiinka oo wuxuu hayaa barta asalka ah ee go'an ee booska qalabka.

III.Qaybta godad

Middi hagaajinta korantada hal shaft

- Xarig-qabasho

〖1〗 Dhexroorka usha

〖2〗 Isku dheeli tiran oo la saxay oo ku xasiloon shaqada

〖3〗 Wacida nadiifinta inta u dhaxaysa duubabka quudinta: gacanta lagu hagaajiyay, habee :0~12㎜

- Habaynta Horizontal ee Kursiga Blade ee Slotting

〖1〗 Dhexroorka usha

〖2〗 Ballaca Goosashada: 7㎜

〖3〗 Daab bir ah:-wheeled iyo kuleyl lagu daaweeyay daawaha birta oo la tiriyey oo leh adayg weyn iyo daal

〖4〗 Daab laba-gees leh: Kuleyl lagu daaweeyay birta daawaha iyo daamurka oo sax ah

〖5〗 Shaagagga curyaanka ah, shaagagga hagaaya warqadda, daabka wax qabad: lagu hagaajiyay PLC, shaashad taabasho ah oo lagu shaqaynayo.

- Habka Hagaajinta Wajiga Slotting

〖1〗 Lagu dhisay gears meeraha.

〖2〗 Wajiga daabacaadda: lagu hagaajiyay 360° si loogu shaqeeyo.

4. Kursiga caaryada ee la qaadi karo

1. Kursiga loogu talagalay ballaca caaryada sare: 100㎜, kursiga hoos u ballaadhinta caaryada: 100㎜ (oo leh saxaarad caag ah).

2.. Godka dhinta ku shubidda waxay samayn kartaa si waafaqsan codsiga macmiilka.

5. Dareeraha xakamaynta

1.Control panel: badhanka joogsiga soo ifbaxa, kaas oo si ku habboon u xakameyn kara nidaamka quudinta warqadda iyo nidaamka daabacaadda, nidaamka goynta

IV.Waaxda is dulsaarka

1. Gacan qaadashada warqad

1.Manual ama hawlgal toos ah ayaa la dooran karaa.

2.Waraaqda hesha suunka cududda cudud, u hagaaji cidhiidhiga si madaxbannaan, iyadoon loo eegin dhererka suunka.

2, nidaamka qaadista Haydarooliga sariirta

1.Siilad xoog leh wadata.

2. Dhererka is dulsaarka: 1600 mm.

3.Sariirta waxaa kor loo qaadaa oo hoos loo dhigaa habka wax-qaadista Haydarooliga, kaas oo sariirta ku haya meel go'an oo aan simbiriirixnayn.

4.Aaladda ilaalinta badbaadada ayaa lagu rakibay si sariirta iyo miiska kor loogu qaado oo ay hoos ugu dhacaan xakamaynta, hubinta badbaadada hawlwadeennada.

5. Suunka fuulitaanka laalaabka fidsan si aanu kartoonku simbiriirixan.

3. Waraaqaha qaata jaahwareerka

1. Waraaqaha ficil-celinta pneumatic ee hela baffle, marka xaashida lagu dhejiyo dhererka hore loo go'aamiyay, warqadda helaysa saxanka taageerada waxay si toos ah u fidisaa si ay u qabato xaashida.

2. Gacanta ku hagaaji booska qaska dambe.