Nuugista faakuumka buuxa ee flexo daabacaadda xawaaraha sare leh & Slotter of ORTIE-II

| Cutubka quudinta | 1 |

| Unug daabacaha | 3 |

| unugga Slotter | 1 |

| Cutubka Gluer Auto | 1 |

Nuugista faakuumka buuxa ee servo-ga xawaaraha sare leh ee daabacaadda Flexo &Slotter&GluerOf ORITE-II (Go'an)

I.Qaybta hawlgalka ee kombuyuutarku maamusho

1, mishiinku wuxuu qaataa xakamaynta kombuyuutarka, darawalka servo ee Japan;

2, cutub kastaa wuxuu ku qalabaysan yahay mashiinka-mashiinka, fududahay in lagu shaqeeyo, hagaajin sax ah, ka dib marka la dhammeeyo gelinta waxay si toos ah u noqon kartaa mid caqli-gal ah guriga ugu dhow iyada oo aan martida loo dhigin hal jihada eber iyo gooyaha, dib ugu noqo labajibbaaran dib u habeynta hufnaanta shaqada hoose;

3, xogta waa la kaydiyaa: Marka xogta saxda ah ee alaabta la warshadeeyay, xogta hadda si toos ah ayaa loo kaydiyaa isticmaalka soo socda;si toos ah loo hagaajiyo iyadoo la raacayo tilmaamaha marka mar kale la isticmaalo, hagaajinta wakhtiga;

4, hagaajin xogta waxaa lagu hagaajin karaa si gaar ah, iyada oo aan la isticmaalin shaqada amarka si toos ah u socodsiin kartaa xogta gelinta madax-bannaan, hoos u dhac weyn oo waqtiga la isku hagaajiyay, ku habboonaanta hababka hawlgalka;

5, soo bandhigida qaladka: waxay u ogolaataa hawlwadeenka cilada mashiinka ku jira, waqti ku ogow sababta cilladda;

6, kombuyuutarka sixitaanka xogta cayriin: Marka xogta asalka ah ay lunto ka dib hagaajinta mishiinka, isticmaaluhu wuxuu si toos ah u hagaajin karaa midabka xogta asalka ah, soo gaabiyo wakhtiga dayactirka, sidaas darteed fududaynta isticmaalaha;

7, xusuusta eber: mashiinka inta ay ku jiraan shaqadooda, fur mashiinka tirtirka mashiinka ama version qadar yar oo mashiinka ayaa si toos ah u soo celin kara booska asalka ah;

8, la koontarooli karo wiishka anilox: Marka koox ku meel gaar ah uma baahna in la daabaco, waxaa lagu xakameyn karaa anilox uma baahna inay hoos u dhacdo, iyada oo aan la nadiifin rullaluistemadka khad;

9, waxay xor u noqon kartaa inay dejiso wakhtiga warqadda jar-jarka, jar wakhtiga u dhexaynta waraaqaha, bixi dabacsanaan ku habboon doorbidyada shakhsiyeed;

10, xawaaraha muujinta muraayadda mashiinka ugu weyn, quudinta, orodka Zhang kasta, labadaba togan iyo kuwa taban;

11, shaashadda ugu weyn waxay muujinaysaa habka loo dejiyay, tirada dhabta ah ee kootada wax soo saarka ayaa la dhammeeyaa si toos ah u joojiya quudinta anilox si toos ah saxanka;

12, amarrada Default: midabka kombayuutarka ee dalabaadka habaynta, kartoonnada gelinta xogta kala duwan;

13, shaashadda quudinta waxay soo bandhigtaa xajmiga booska tailgate waxayna leedahay shaqada ilaalinta qaylo-dhaanta sare iyo hoose;

14, hawlgalka mishiinka shaqada shil, bandhigga shaashadda ayaa si xad dhaaf ah u buuxsamay oo si toos ah u xiran;

15, marka la wanaajiyo software-ka shirkadda, saddex sano gudahood casriyaynta bilaashka ah;

16, Wasaaradda quudinta, daabacaadda, dhimista auto-eber.

II.Cutubka quudinta

Qaybta quudinta waxay isticmaashaa tignoolajiyada quudiyaha cidhifka rasaasta ", oo ku habboon dhammaan noocyada jiingadaha;

U soo dir rullaluistemadka quudinta ay wadaan matoorada servo, iyada oo aan lahayn khalad gudbinta farsamada;

Vacuum auxiliary auxiliary to feeder feeder, cadaadiska hawada waxaa lagu hagaajin karaa iyadoo loo eegayo cabbirka warqadda.

1,Xajinta mashiinka

1).

2), Qalab kasta oo ka mid ah saldhigyada landline-ka ee joogsiga degdega ah, koontarool gudaha ah si loo joojiyo dhaqdhaqaaqa mashiinka si loo hubiyo amniga shaqaalaha gudaha.

3), aaladda qufulka pneumatic.

4) waxay noqon kartaa mid joogto ah ama ka boodi kartaa quudinta.

2, Nidaamka Vacuum

1), oo lagu qalabeeyay qashinka nuugista iyo mashiinka ka saarida boodhka iyo rullaluistemadka dhejiska ah, waxay baabi'in kartaa tiro badan oo ka mid ah wasakhda dusha daabacaadda kartoonada, hagaajinta tayada daabacaadda.

3, Wakaalada Saxaafadda Xorta ah (Ikhtiyaar)

1) Habka cadaadiska xorta ah wuxuu ka dhigayaa guddiga jiingadaha cadaadiska;iska ilaali baakadaha dhex galka ah inay u muuqdaan kuwo naxay oo xalliya sabuuradda dharka lagu dhaqo waxay dhacdaa marka goobta daabacaada;Marka labaad looma baahna in la hagaajiyo quudinta si joogta ah, waxay daabacan kartaa joogtaynta.

2), iyada oo aan loo baahnayn hagaajinta cadaadiska, wakhtiga hawlgalka kaaliyaha ayaa ku dhow dayacan;halka isbeddel yar oo ku yimaada wax soo saarka caadiga ah ee dhumucda kartoonada aysan saameyn ku yeelan saxnaanta quudinta, iyo in la hubiyo 100 boqolkiiba heerka wax soo saarka.

3) Ma jiro warqad quudin ah, si looga fogaado isbeddelka xawaaraha khadka sababtoo ah xirashada iyo jeexjeexa ay keento khaladaadka romomatic roller-ka ee ay keento daabacaadda.Si loo hubiyo tayada badeecada iyo baahida loo qabo rollers beddelka joogtada ah.

4).

4.

1), quudinta hareeraha dabada, sanaadiiqda qalabka danbe ee koronto ahaan lagu hagaajin karo, iyo shaqada orodka.

2), isticmaalka guud ee qalabka eber ee tooska ah, isku day inaad daabacdo laba si aad ula qabsato booska saxda ah, yareyso qashinka kartoonada.

III.Qaybta daabacaadda

Unug daabacaadda mashiinnada badan ee wadista servo motor si madax-bannaan u kexeeya, baabi'iya qaladka isugeynta nidaamka;

Gaadhida rullaluistuyada ee la caawiyey si loo hubiyo saxnaanta daabacaadda chromatic +0.3 mm;

Matoorka AC servo oo aan lahayn gudbin dib-u-celin ah, nidaamka sahayda saliidda sifaynta marshada looma baahna.

1,rullaluistemadka daabacaadda

1), Dhexroorka dibedda Φ393.97mm ah (dhexroor saxan daabacan ah waa Φ408.37mm).(1200)

2), rullaluistemadka taarikada madaxa oo deminaysa, oo dabcinaysa tuubada oo dhan marka lagu daro walaaca.

3), hagaajinta dheelitirnaanta joogtada ah iyo firfircoonida, hawlgal siman.

4), shiidid dusha sare, dhejinta chrome adag.

5), nooca gariiradda go'an ee ratchet shaft.

6).

7), isticmaalka machadyada nooca laalaada, rakibaad ku habboon, oo ku habboon nooca 10mm ka laadlaadda.

8), daabacaadda gacanta, lugaha beddelka kontoroolka koronto oo togan.(Sare iyo hoose)

9).

2, rullaluistemadka platen daabacaadda

1), Dhexroorka dibadda ee Φ152.2mm.

2), shiidid dusha birta ah, dahaadhay chrome adag.

3), hagaajinta dheelitirka, hawlgal siman.

4), hagaajinta ibta daabacaadda, isticmaalka kombiyuutarada iyo kontoroolka dhijitaalka ah ee elektarooniga ah

3, xargaha sare ee dhoobada anilox roller

1), Dhexroorka dibadda ee Φ206.65mm.(1000,1200)

2), oogada birta ka dib farshaxan reticulate processing gaar ah.

3), oo waafaqsan meelaha khadku ku yaal si siman, waara, oo waara.

4), calaamadaynta tignoolajiyada farsamaynta gaarka ah si loo kordhiyo nolosha saxanka;

5), qol gaar ah oo aluminium squeegee ah oo shaabadaysan, sidaa darteed awoodda foorarsiga ayaa kordhay 30%, badbaadinta 20% kaydka sahayda khad;

6), oo lagu daboolay lakabka cagaaran ee PTFE, si sahlan loo nadiifiyo godka aan dhegta lahayn;

7), isticmaalka farsamada nooca anilox ee degdega ah.

5 habka hagaajinta wajiga

1), cutub kastaa waa servo synchronous drive madax banaan si loo baabi'iyo qaladka daabacan ee urursan.Hindida Roller-ka indheergaradka ah nidaamka meelaynta tooska ah, saxanka usbuuca ka dib saxnaanta dib u habeynta wareejinta ee u dhow khalad eber.

2), booska dambe ee hagaajinta korantada ee kontoroolka shaashadda taabashada PLC, hagaajin masaafada 20 mm, saxnaanta qaabeynta wajiga ilaa 0.10 mm.

6. wareegga khadka

1), bamka diaphragm pneumatic, xasiloonida khad, hawl fudud iyo dayactir.

2).

3), shaandhada khad, shaandheeya wasakhda.

IIII.Halbeegga Slotter (hal set)

Xaqiijinta xajinta: ± 1.5mm

1, giraangiraha siliga

1) ,Dhexroorka shaftΦ154mm, ka dib laba shiidi, chrome adag oo dahaadhay, dhaqaaq siman.(1200)

2) , farqiga riixaya rullaluistemadka miisaanka hagaajinta Buugga, kala duwan ee hagaajinta 0-12mm.

3), Xariiqda cadaadiska wareegga isticmaalka tayada polyurethane laga keeno

2.Slot mindi simbiriirixan habka hagaajinta

1) ,Dhexroorka usheeda dhexe Φ174mm ka dib laba shiidi, chrome adag oo dahaadhay, dhaqaaq siman.(1200)

2)

3) Alloy Tool steel kulayl-la daaweeyay, shiidi mindi jeexan, engegnaanta iyo adkaanta waa heer sare ah.(Taiwan)

4) Alloy steel ka dib daawaynta kulaylka, shiida mindi gooyn, mindi af badan, iyo sax sare.

5), giraangiraha khadka cadaadiska, rullaluistemadka hagaha, booska mindida booska, isticmaalka kontoroolka isku xidhka badhanka korontada.

6)

Nidaamka Xabagta V.

Dayactirka fudud, dhimista kharashka dayactirka.

Wareegga nuugista bamka Peristaltic, yaraynta qashinka koollada.

Qeybta Gaadiidka:

Waxay la qabsan kartaa dhumucda kala duwan ee kartoonada oo leh qalabka hagaajinta farqiga, oo ka soo baxa saxafada ka soo baxa kartoonada tooska ah.

Unug laablaaban

Rakibaadda hab cusub oo laalaabid, iyadoo la siman laabidda saxda ah, gooynta farqiga wuxuu noqon karaa kor iyo hoos.

Isticmaalka nooca nuugida suunka ugu weyn, dheecaanka siman ee heerka ugu dambeeya ee kartoonka laalaabida, geesaha kartoonada si looga hortago qallooc.

Bidix iyo midig laba suunka laablaaban oo leh matoor gooni ah, iyadoo loo eegayo cabbirada dhererka iyo ballaca xawaaraha si gaar ah loo xakameeyey.

Cutubka tirinta iyo ka saarida

kartoonada yaryar waxay ku gaari karaan inay si habsami leh u socdaan xawaare sare.

Nooca dibadda ku xidhan, dalool la qaadi karo, nooca hawo-mareenka ayaa sidoo kale noqon kara mid deggan, si habsami leh ugu dheji sanduuqa warqadda.

Unugga Hawlgalka:

Habee shaashadda taabashada LCD midabka, waxaad soo bandhigi kartaa noocyo kala duwan oo ah macluumaadka alaarmiga iyo macluumaadka hawlgalka.

Gaadhi kantaroolka fogaanta.

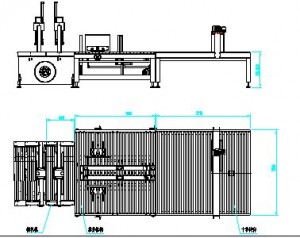

VI, cabbirada farsamada ugu weyn

| Tilmaamid | 1800*1000 | 2200*1000 | 1800*1200 | 2500*1200 |

| Xawaaraha ugu badan | 200 | 200 | 180 | 170 |

| Cabbirka quudinta ugu badan (mm) | 1800*970 | 2200*970 | 1800*1170 | 2800*1200 |

| Ka bood cabbirka quudiyaha (mm) | 1800*1200 | 2200*1200 | 1800*1400 | 2800*1400 |

| Cabbirka quudinta ugu yar (mm) | 650*280 | 650*280 | 650*340 | 650*400 |

| Aagga daabacaadda ugu badan (mm) | 1750*920 | 2150*920 | 1750*1120 | 2750*1150 |

| Dhererka saxanka daabacan (mm) | Sida baahida macaamiisha | |||