Sameeyaha Sanduuqa Adag ee RB420B

| RB420B Sameeyaha sanduuq adag oo otomaatig ah | |||

| 1 | Cabbirka warqadda (A×B) | Aamiin | 100mm |

| Amax | 580mm | ||

| Bmin | 200mm | ||

| Bmax | 800mm | ||

| 2 | Dhumucda warqadda | 100-200g/m2 | |

| 3 | Dhumucda kartoonada (T) | 0.8-3mm | |

| 4 | Badeecada dhammaatay (sanduuqa) cabbirka(L×W×H) | L×W Min | 100×50mm |

| L×W Max | 420×320mm | ||

| H Min. | 12 | ||

| H Max. | 120mm | ||

| 5 | Cabbirka warqadda laalaabsan (R) | Rmin | 10mm |

| rmax | 35mm | ||

| 6 | Saxnaanta | ±0.50mm | |

| 7 | Xawaaraha wax soo saarka | ≦28 xaashi/daqiiqo | |

| 8 | Awoodda matoorka | 8kw/380v 3 waji | |

| 9 | Awoodda kulayliyaha | 6kw | |

| 10 | Bixinta hawada | 10L/daqiiqo 0.6Mpa | |

| 11 | Miisaanka mashiinka | 2900kg | |

| 12 | cabbirka mashiinka | L7000×W4100×H2500mm | |

1. Cabbirrada ugu badan iyo kuwa yar-yar ee sanduuqyada ayaa la hoos geeyaa kuwa waraaqaha iyo tayada warqadda.

2. Awoodda wax-soo-saarka waa 28 sanduuq daqiiqaddii. Laakiin xawaaraha mishiinku wuxuu ku xiran yahay cabbirrada sanduuqyada.

3. Ma siinno kombaresarka hawada.

Xidhiidhka u dhigma ee u dhexeeya halbeegyada:

W+2H-4T≤C(Max) L+2H-4T≤D(Max)

A(daqiiqo)≤W+2H+2T+2R≤A(Max) B(min)≤L+2H+2T+2R≤B(Max)

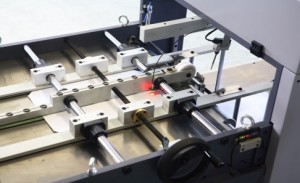

1. Quudiye mashiinkani wuxuu qaataa nidaamka quudinta gadaal-u-riix, kaas oo lagu xakameynayo sambabada, qaab-dhismeedkiisuna waa mid fudud oo macquul ah.

2. Balaadhka u dhexeeya is dulsaarrada iyo miiska quudinta waxa lagu hagaajiyay dhexda. Qalliinku waa mid aad u fudud oo aan loo dulqaadan karin.

3. xoqoor cusub oo naxaas nashqadeeyay ayaa si cufan ula shaqeeya rullaluistuyada, isaga oo si wax ku ool ah uga fogaanaya dabaysha waraaqaha. Iyo xoqida naxaasta waa mid aad u waara.

4. Samee tijaabiyaha xaashida labanlaabka ah ee ultrasonic ee laga soo dhoofiyo, oo ka muuqda hawlgal fudud, kaas oo ka ilaalin kara laba warqadood inay soo galaan mashiinka isku mar.

5. Wareegga tooska ah, isku dhafka iyo nidaamka dhejinta ee koollada kululaynta. (Qalabka ikhtiyaariga ah: mitirka viscosity mitir)

6. Cajalad kulul oo dhalaalaysa si toos ah u gudbinta, goynta, iyo dhamaystirka dhajinta sanduuqa gudaha ee quad joogista (afar xagal) ee kartoonada hal habraac.

7. Marawaxada nuugista faakuumka ee hoos timaada suunka qaada waxa ay ka ilaalin kartaa in warqaddu ay leexato.

8. Sanduuqa gudaha ee xaashida iyo kartoonada waxay adeegsadaan aaladda hagaajinaysa biyaha si ay si sax ah u aragto.

9. Duubabka ayaa si joogto ah u duubi kara, laab laabaya dhegaha iyo dhinacyada warqadaha oo u samayn kara hal hab.

10. Mashiinka oo dhan wuxuu shaqeeyaa PLC, nidaamka raadinta korantada iyo HMI si ay si toos ah u sameeyaan sanduuqyada hal hab.

11. Waxay si toos ah u baari kartaa dhibaatooyinka iyo qaylo-dhaanta si waafaqsan.