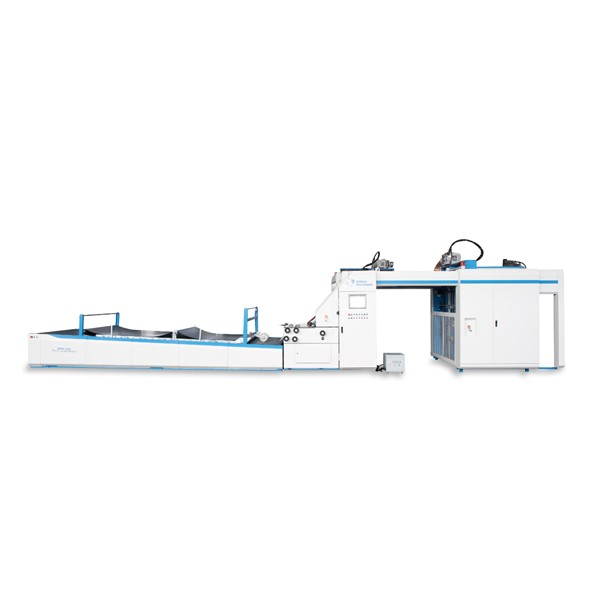

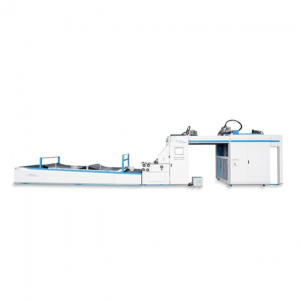

EUFM Mashiin xawaarihiisa sareeyo oo toos ah

Warqadda waxaa lagu dhejin karaa sabuuradaha si loo kordhiyo xoogga iyo dhumucda walxaha ama saamaynta gaarka ah. Dhimashada ka dib, waxaa loo isticmaali karaa baakadaha baakadaha, boodhadhka iyo ujeedooyin kale.

| Qaabka | EPFM1450 | EPFM1650 | EPFM1900 |

| Cabirka ugu badan | 1450*1450mm | 1650*1650mm | 1900*1900mm |

| Cabirka min | 380*400mm | 400*450mm | 450*450mm |

| Warqad | 120-800g | 120-800g | 120-800g |

| Warqadda hoose | ≤10mm ABCDEF looxa jiingado ≥300gsm kartoonada | ≤10mm ABCDEF looxa jiingado ≥300gsm kartoonada | ≤10mm ABCDEF looxa jiingado ≥300gsm kartoonada |

| Xawaaraha ugu sarreeya ee laminating | 150m/daqiiqo | 150m/daqiiqo | 150m/daqiiqo |

| Awood | 25kw | 27kw | 30KW |

| Ku dheji saxnaanta | ±1.5mm | ±1.5mm | ±1.5mm |

1.QUUDINTA XAASHIDA GUN

Adeegso nidaamka kontoroolka korantada ee matoorka Servo, oo leh suunka nuugista Japan ee NITTA si aad u samayso beddelka tamarta nuugista, iyo suunka lagu nadiifiyo rullalusha biyaha; Tignoolajiyada rukhsadda leh si loo hubiyo in corrugate iyo kartoonada ay u baxaan si habsami leh oo hawl fudud.

2.MAQAANKA XAASHIDA QUUDINTA SARE

Labada warqad qaadasho iyo biibiile quudinta ee xawaaraha sare ee feediyaha gaarka ah ayaa si xor ah loo hagaajin karaa si loogu waafajiyo warqad khafiif ah iyo mid dhumuc leh labadaba. Si wada jir ah oo leh bamka Becker, hubi in warqadda quudinta sare ay si degdeg ah oo habsami leh u socoto.

3.NIDAAMKA KORONTADA

Naqshadeeyay oo la qaatay kontaroolaha dhaqdhaqaaqa USA Parker oo ay weheliyaan nidaamka Yaskawa Servo iyo beddelka, Siemens PLC si loo hubiyo in mashiinku uu ku socdo ugu badnaan. xawaaraha iyo saxnaanta sida waxqabadka sare iyo xasilloonida socodsiinta.

4.QAYBTA-DHAQAANKA KA HOR

Nadaamka xirxiran ee leh hawl hore loo dejiyay waxa loo dejin karaa cabbir ahaan warqad iyada oo loo marayo shaashadda taabashada oo si toos ah u jihaysan si loo yareeyo waqtiga habaynta si hufan.

5.Nidaamka Gudbinta

suunka isku midka ah ee Gates oo ay la socdaan SKF sida gudbinta ugu weyn ayaa la qaatay si loo xaqiijiyo xasilloonida. Labada rullaluistemadka cadaadiska, rullalulatada qoyaanka ah iyo qiimaha koolladaba si fudud ayaa loogu hagaajin karaa iyada oo gacanta lagu hayo codeeyaha farsamada.

6.NIDAAMKA POSITIONING

Photocell oo ay weheliso Parker Dynamic module iyo nidaamka Yaskawa Servo waxay xaqiijiyaan saxnaanta jihaynta warqadda sare iyo hoose. Rolalaha xabag-la'aanta ah oo leh anilox shiidid wanaagsan si loo dammaanad qaado xitaa dahaarka xabagta xitaa min min. tirada xabagta

7. Shaashadda taabashada iyo hanuuninta tooska ah

Qaabka warqadda waxaa lagu dejin karaa iyada oo loo marayo 15inch Touch Monitor oo ku jihaysan matoorka beddelka si toos ah si loo yareeyo waqtiga dejinta. Jihaynta otomaatiga ah waxa lagu dabaqaa unugga hore u-tusin, unugga quudinta sare, unugga quudinta hoose iyo unugga meelaynta. Badhanka taxanaha Eaton M22 wuxuu xaqiijiyaa wakhtiga dheer ee shaqada iyo quruxda mashiinka.

8.QABASHAHA

Cutubka gudbinta ee kor loo qaaday ayaa u sahlaya hawlwadeenka inuu soo dejiyo warqad. Cutubka gudbinta dheer oo ay weheliso suunka cadaadiska si ay shaqada dahaadhka uga dhigaan si degdeg ah u engegan.

9.NIDAAMKA SUUQAYNTA automatiga ah

Bamka sifaynta tooska ah ee dhammaan xadhkaha muhiimka ah waxay xaqiijiyaan mashiinku adkeysi xoogan xitaa marka lagu jiro xaalad shaqo oo culus.

Ikhtiyaarada:

1.Nidaamka quudinta cidhifyada

Cidhifka rasaasta waxay hubisaa looxa jiingadaha qaro weyn sida 5 ama 7 lakab inay si habsami leh u socdaan xataa xaalad aad u bogsanaysa.

2. QUUDIYAHA ADEEGGA OO FURSAD AH

Quduudaha servo feeder-la'aanta waxaa loo isticmaalaa xaashi dheer oo dheeri ah oo dhaqdhaqaaq dabacsan.

3.Ilaalinta Badbaadada iyo Badbaadada dheeraadka ah

Daboolka dheeraadka ah ee xiran agagaarka mashiinka si loogu caawiyo badbaadada dheeraadka ah. Gudbinta badbaadada si loo hubiyo in albaabka beddelka iyo joogsiga E-joojinta si xad dhaaf ah u shaqeeyo.